Injection moulding company Wicro Group

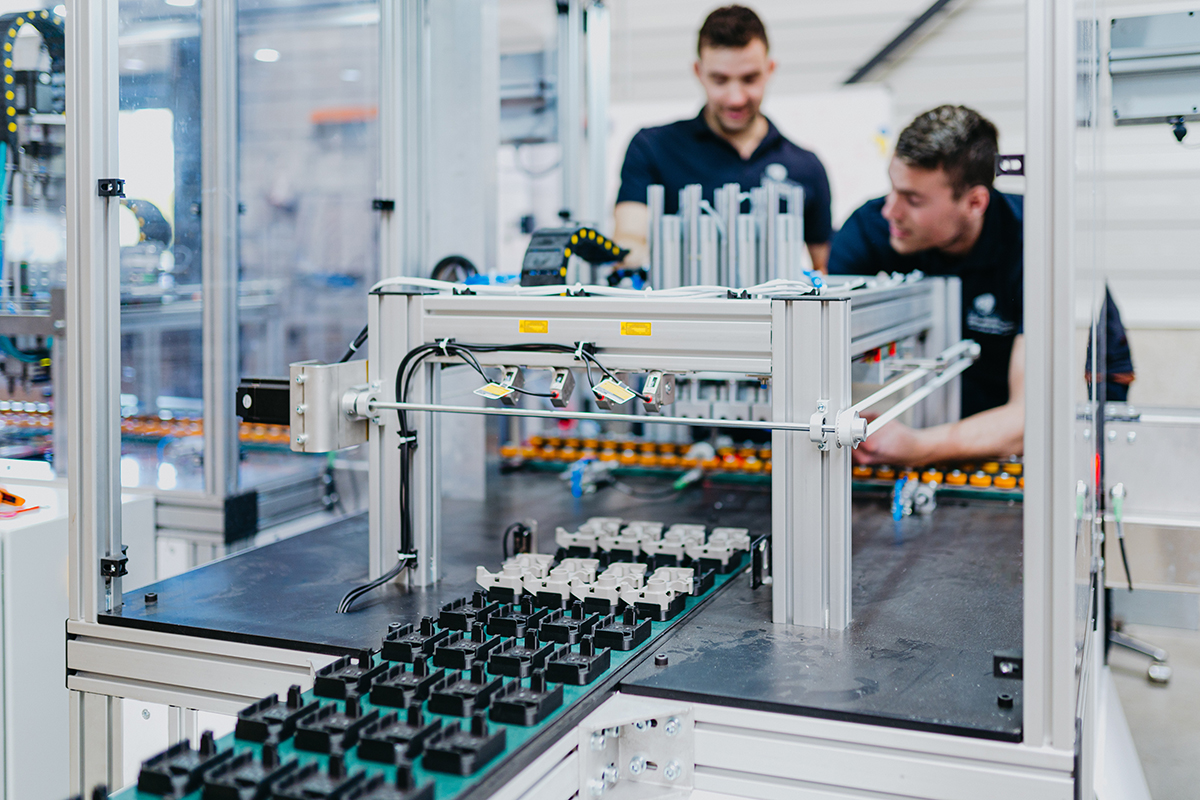

We, Wicro Group, are a renowned European injection moulding company. We serve our partners in the Netherlands and beyond from our base in Kessel, in Limburg. As an injection moulding company, we’re always actively involved in the creation of the final product, which means that we don’t limit ourselves to plastic injection moulding. We develop the moulds, have our own assembly line, and take care of the distribution too. As a one-stop shop, we give advice on efficiency and how to save on injection molding costs.