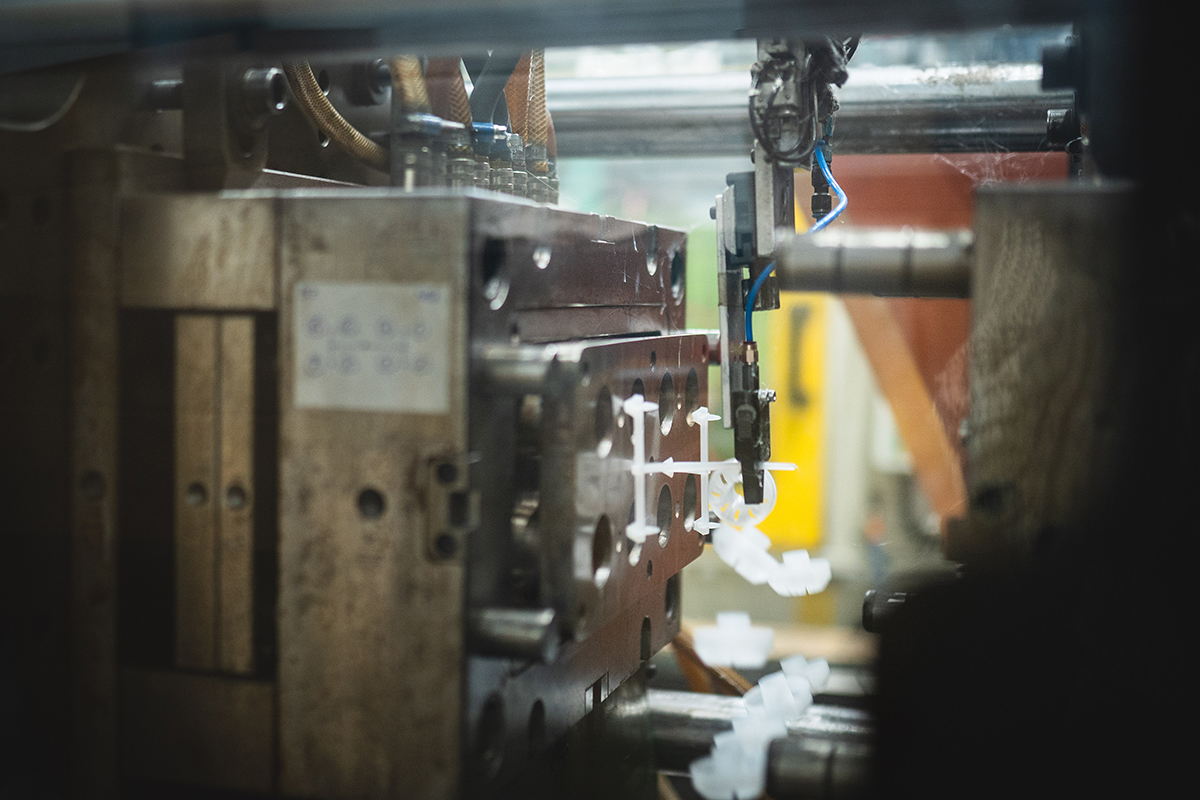

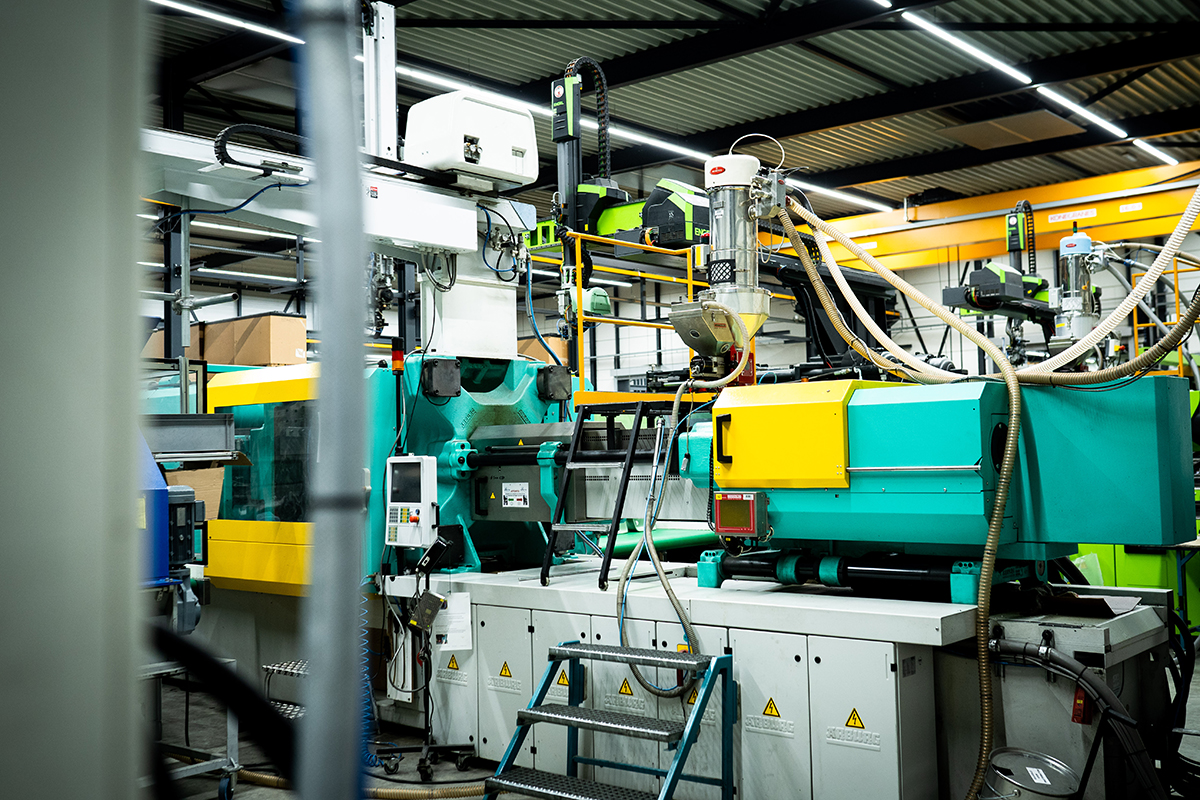

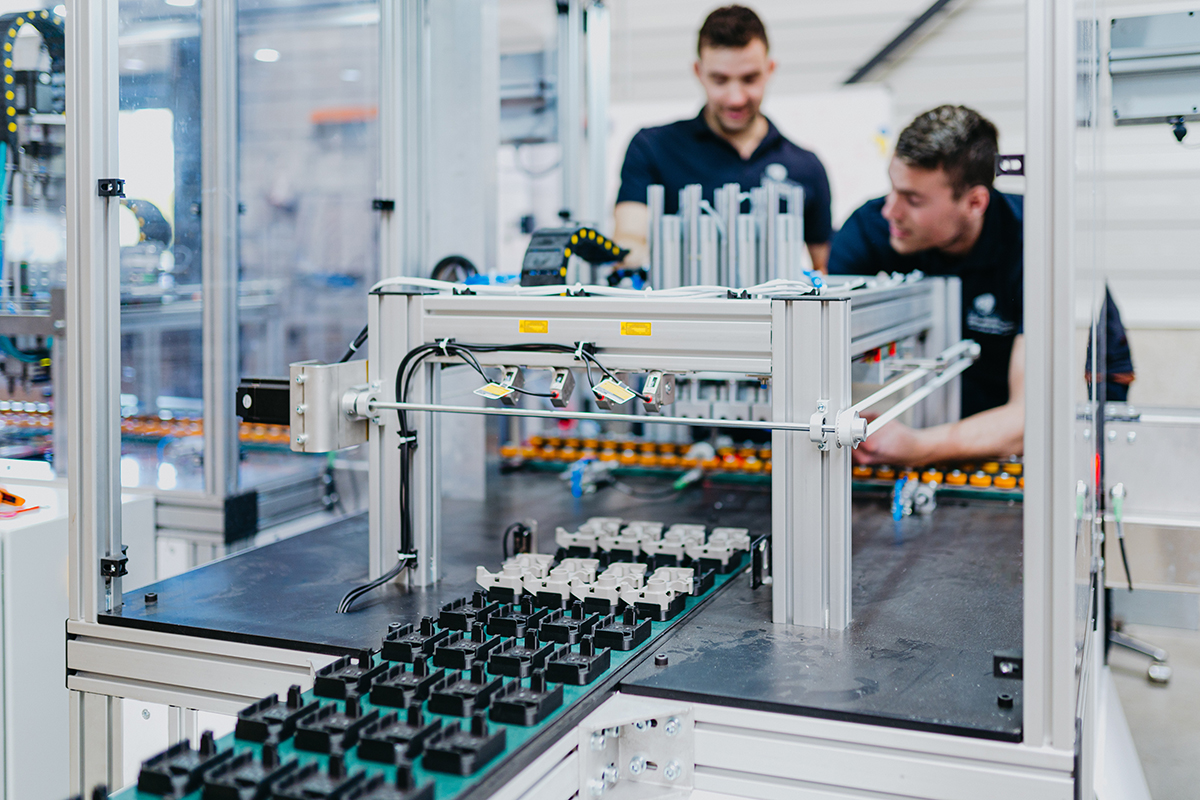

Injection mould

Moulds are used for injection moulding. Injection moulding can’t be done without an injection mould. A mould consists of two steel parts with a cavity between them. The cavity is the reverse, the negative, of the final product. Injection moulds can also be made from aluminium or another metal. At Wicro Plastics, our standard material is high-quality Western European steel. The specific type depends on the raw material used for the product, and the annual volume required.

Each of the two parts of the injection mould has a different shape and function. One part is the injection side (front mould) and the second part is the ejection side. The injection side is fixed to the machine and the ejection side moves during the cycle of each product. Each product or component has its own unique injection mould.