Have plastic product made

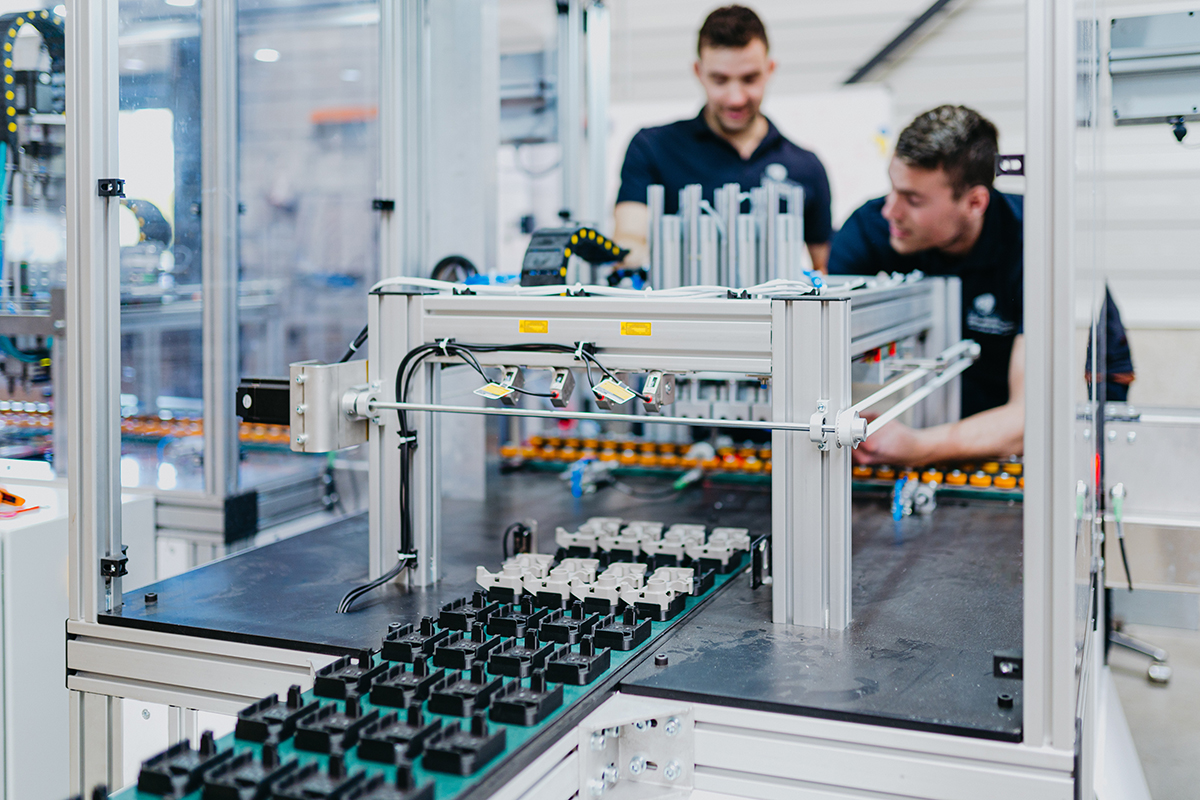

Plastic products are something that we all use every day, and many are manufactured using injection moulding. Injection moulding can create almost any unique shape. In collaboration with our engineers, the product’s manufacturability, reproducibility and costs will be examined. After all, the price is something that’s determined on the drawing board. Our engineers have plenty of experience; they supervise similar design projects an average of 100 times each year.