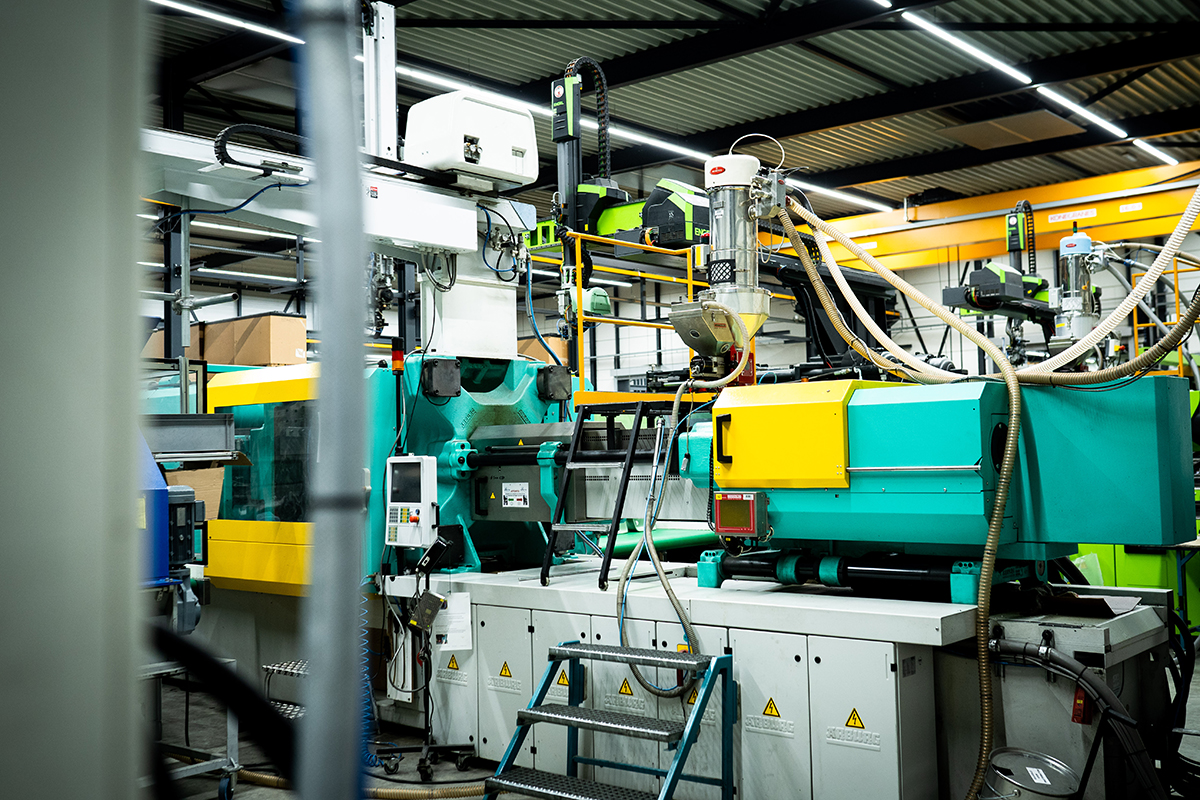

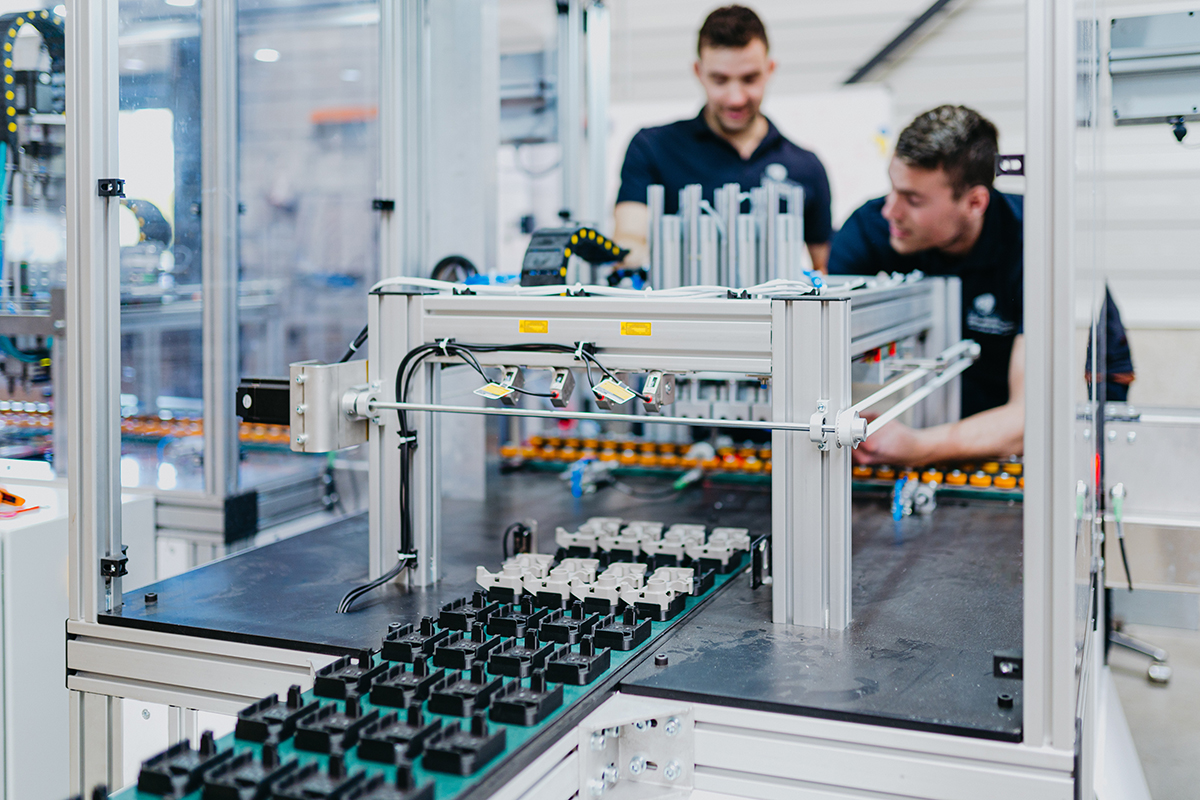

From product design to manufacturability

The transition from product design to manufacturability is a crucial step in product engineering. Together we arrive at a detailed design, and our engineers perform a manufacturability analysis. We take a critical look at various factors including the desired material, wall thickness, mould options, production techniques, and potential automation. Because we have in-house engineers at Wicro and work closely with mould-makers in China, Portugal and the Netherlands, the lines of communication are short. This enables us to make the right choices efficiently and with all knowledge already in-house.