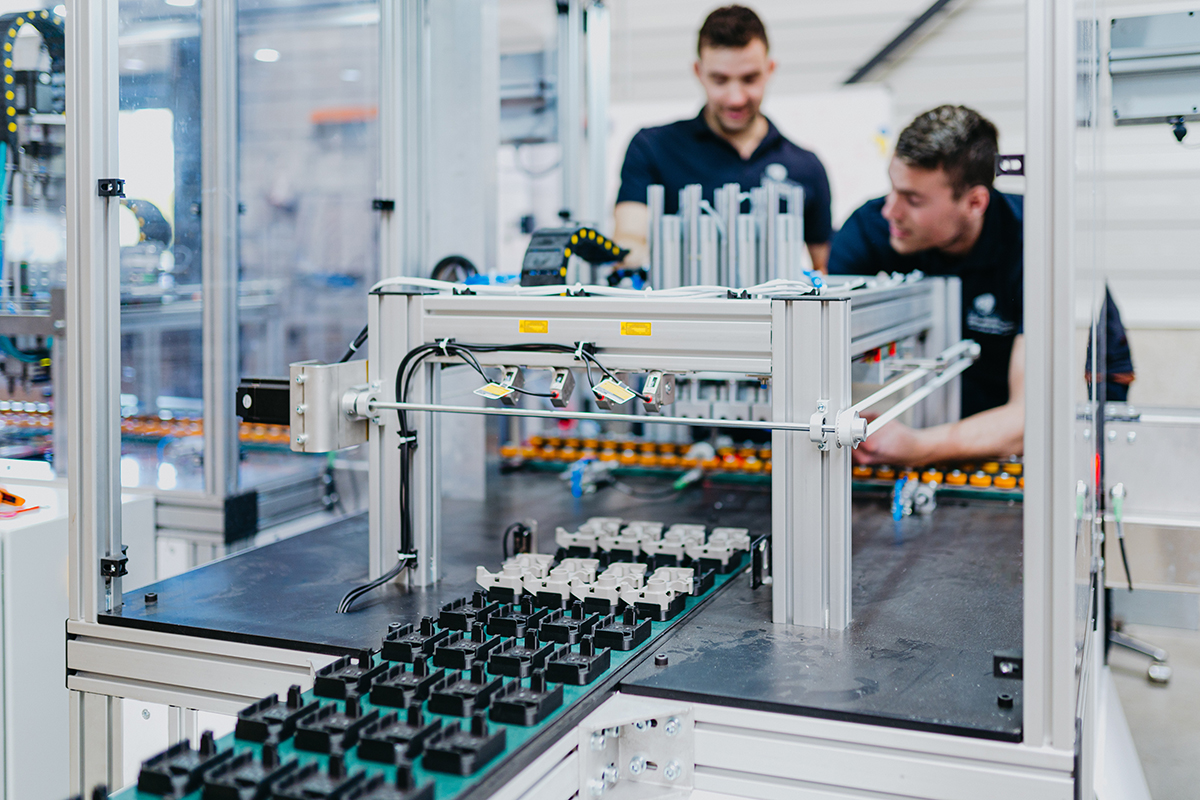

Process automation as the key to success

In the quest for improved efficiency, we’ve invested in process automation at Wicro. In recent years we have integrated generic and product-specific automations and robots into our injection moulding and assembly lines, ensuring fast, streamlined and accurate production for a wide range of products. Thanks to the latest technologies and careful programming, we have precise control over every step of the process. Despite the wide range of products and customers, we’re able to find a suitable solution for every customer.