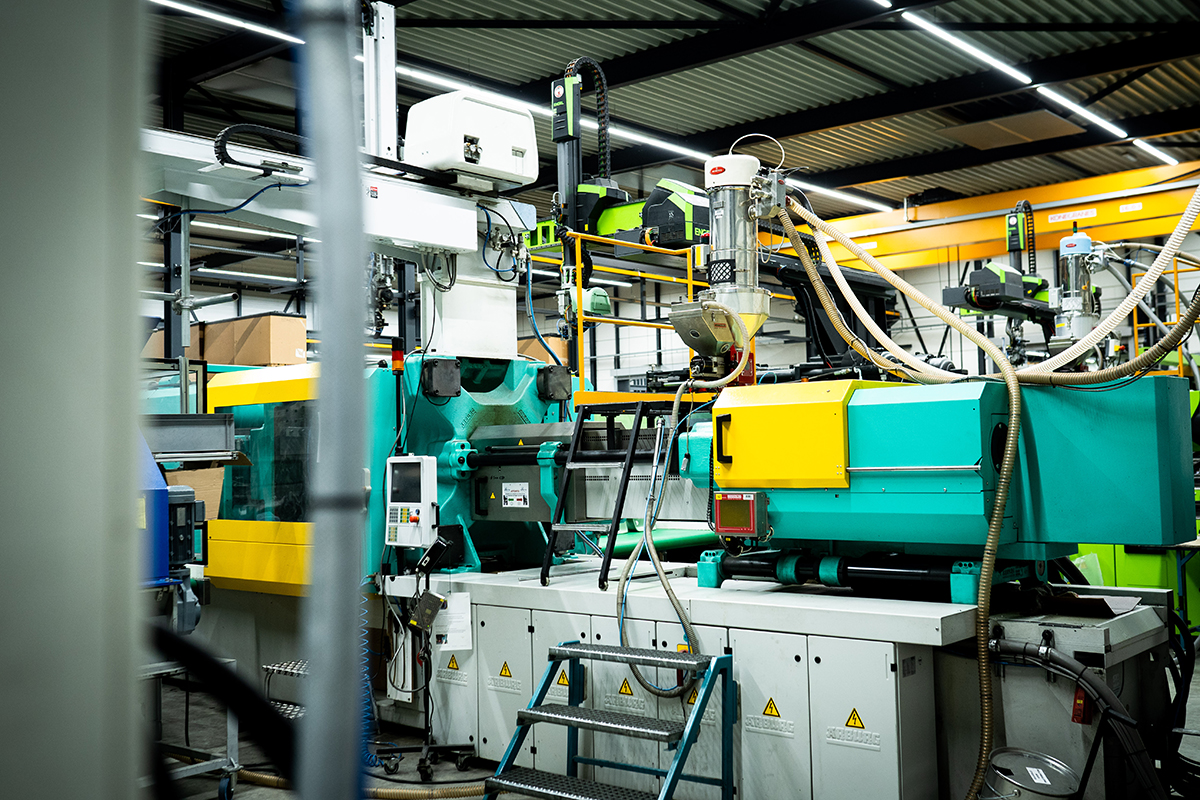

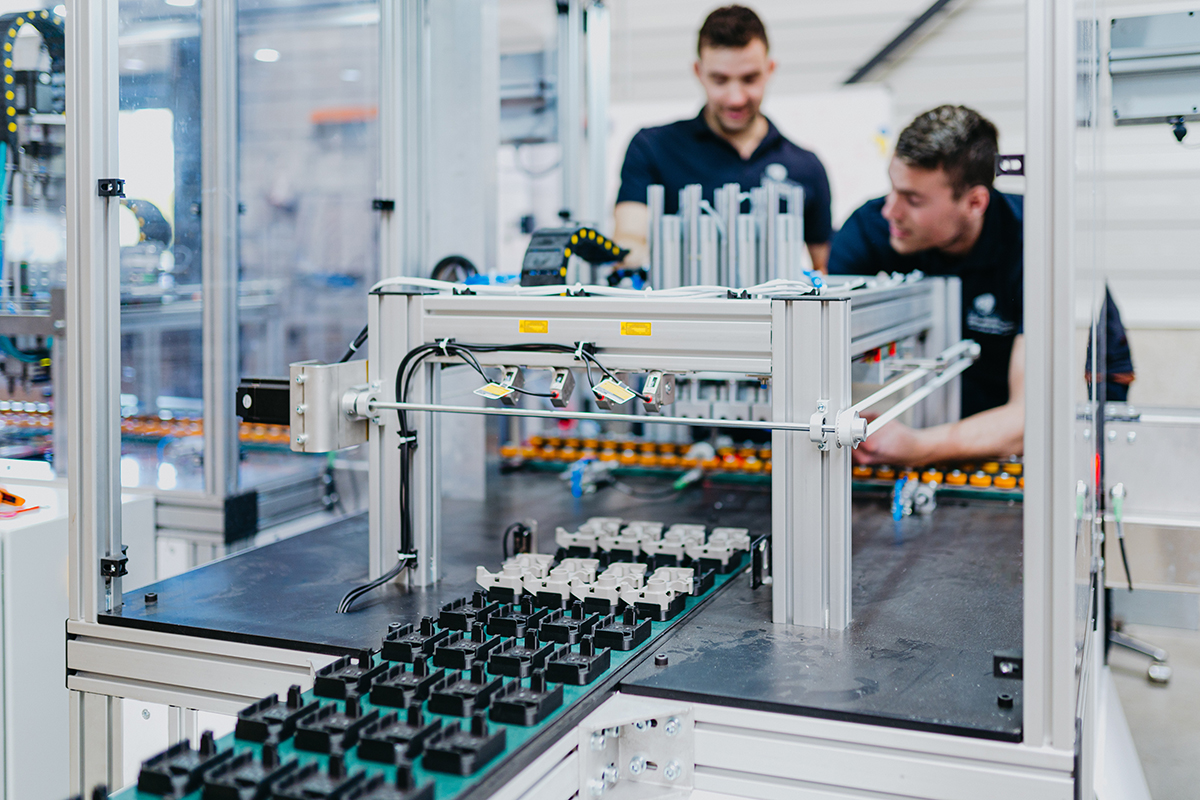

Plastic moulding

Complex shapes or important safety requirements? When it comes to plastic moulding, anything is possible. Developing an injection moulding machine enables plastic to be moulded into any component you need. An injection mould is precision-designed in collaboration with an engineer. Once it has been created, it’s easy to handle high production numbers. Injection moulding is known for its extremely detailed results. It’s a pleasure to see how a product or component comes out of the injection moulding machine, very quickly and often without any post-processing.