Assembly and procurement

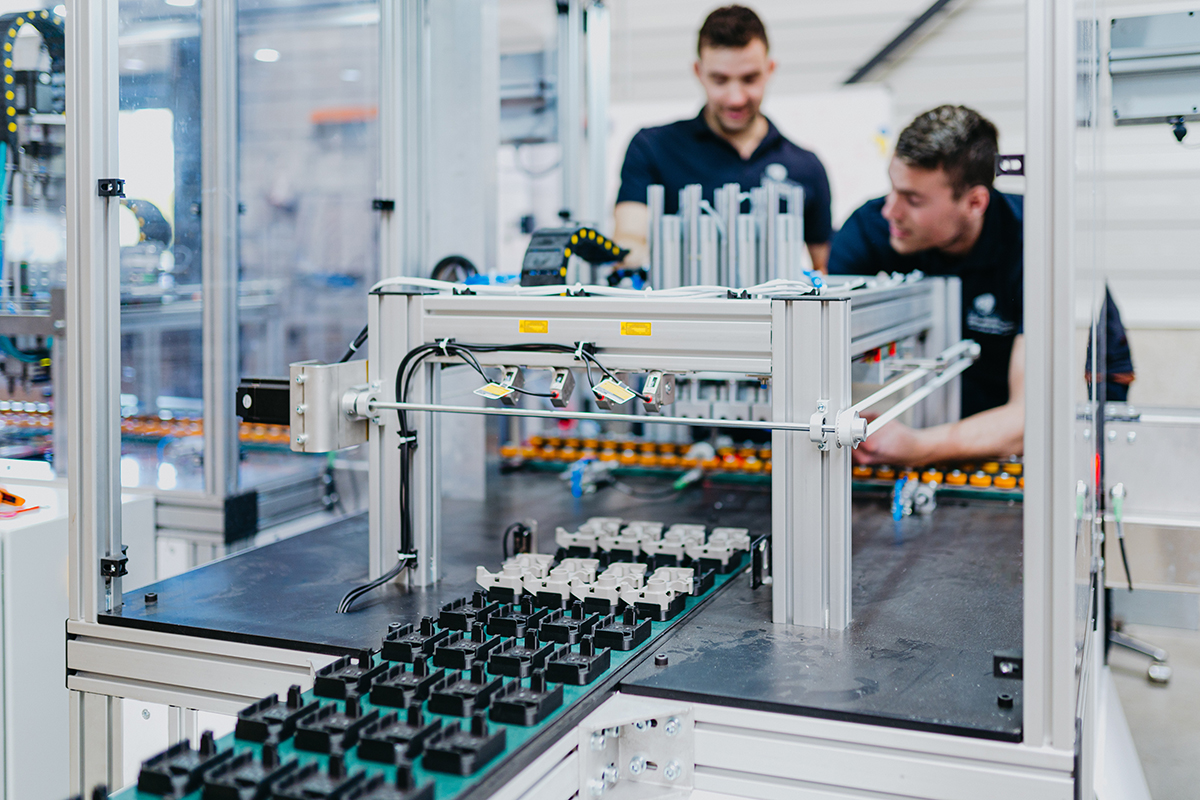

Do you have a product that you want Wicro to assemble? We’ll create a product-specific assembly line for it. Automation may be used, depending on the annual volume, the complexity, and the checks required. In some cases assembly requires a great deal of manual work.

Wicro Group will produce the plastic components of your end product using injection moulding. Wicro is also able to source (and ultimately procure) all other components, made of materials other than plastic and produced by other manufacturers. We take care of the entire selection and audit process. Wicro then ensures that all the components required for your end product are in stock, so we can assemble your order right away and guarantee fast delivery.