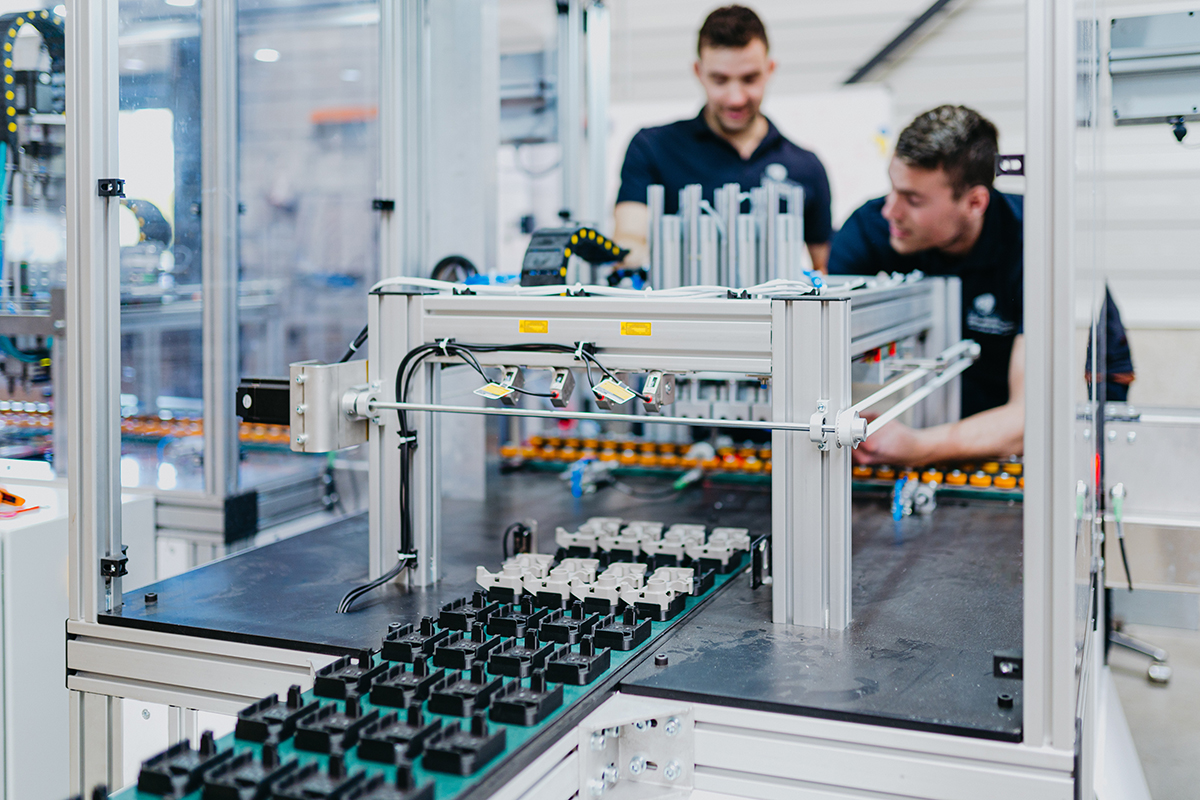

To the last detail: Stage-Gate Model

Whatever the project, nothing escapes our attention and we don’t miss a single detail. At Wicro, we use a tested Stage-Gate Model to manage projects efficiently and ensure their success. The model consists of several stages, each one concluding with a gate review. These reviews assess whether the project has achieved the set criteria before it moves on to the next phase. This ensures that together we make good decisions and that the project’s progress is closely monitored. This avoids risk and enables us to plan with the greatest of care.