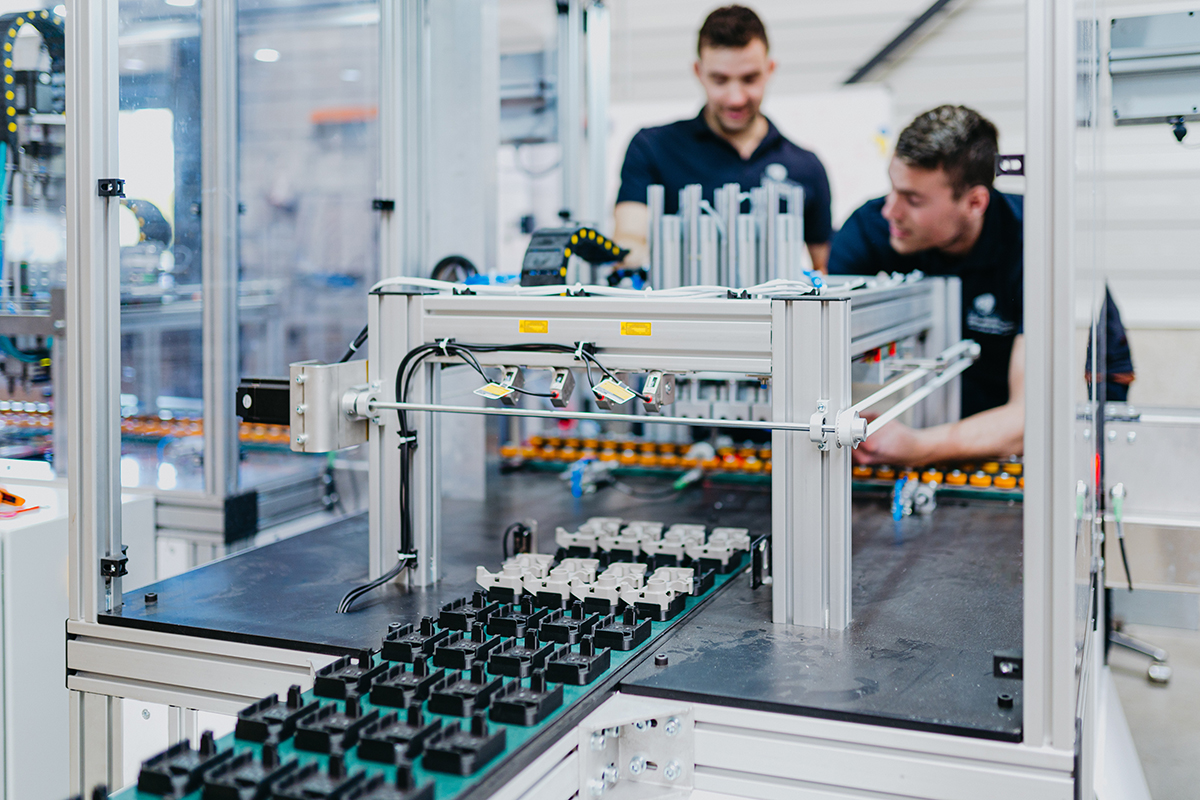

Plastic components

It’s something all we see every single day. A lot of the products around us are made of plastic. Plastic components make a product easy to use and give it a lovely shape. There are various plastic components that make a particular product practical to use, for example a thermostat display, a waste bin lid, or pram wheels. These are just three of the countless examples of plastic components that form an important part of the overall product. Plastic’s biggest advantage is that it can be moulded into (almost) any shape you might want. Many types of plastic are easy to colour and plastic is light, strong and sustainable.