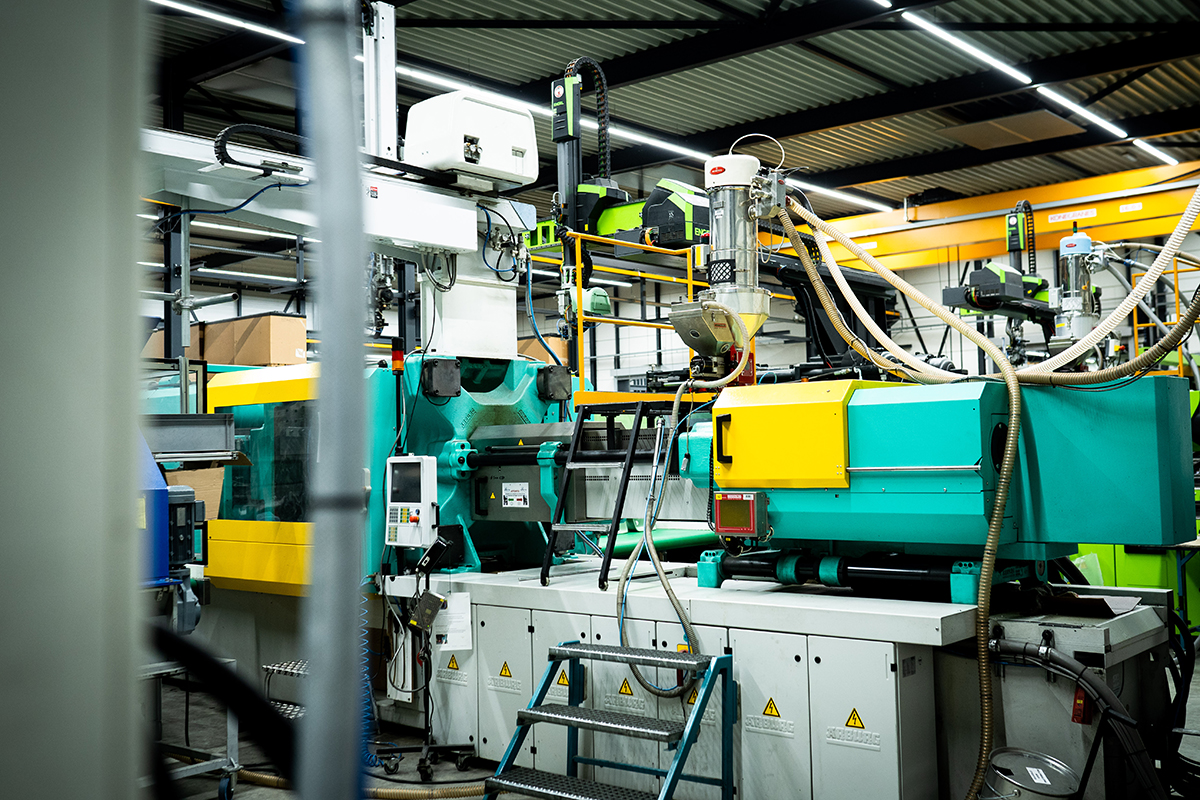

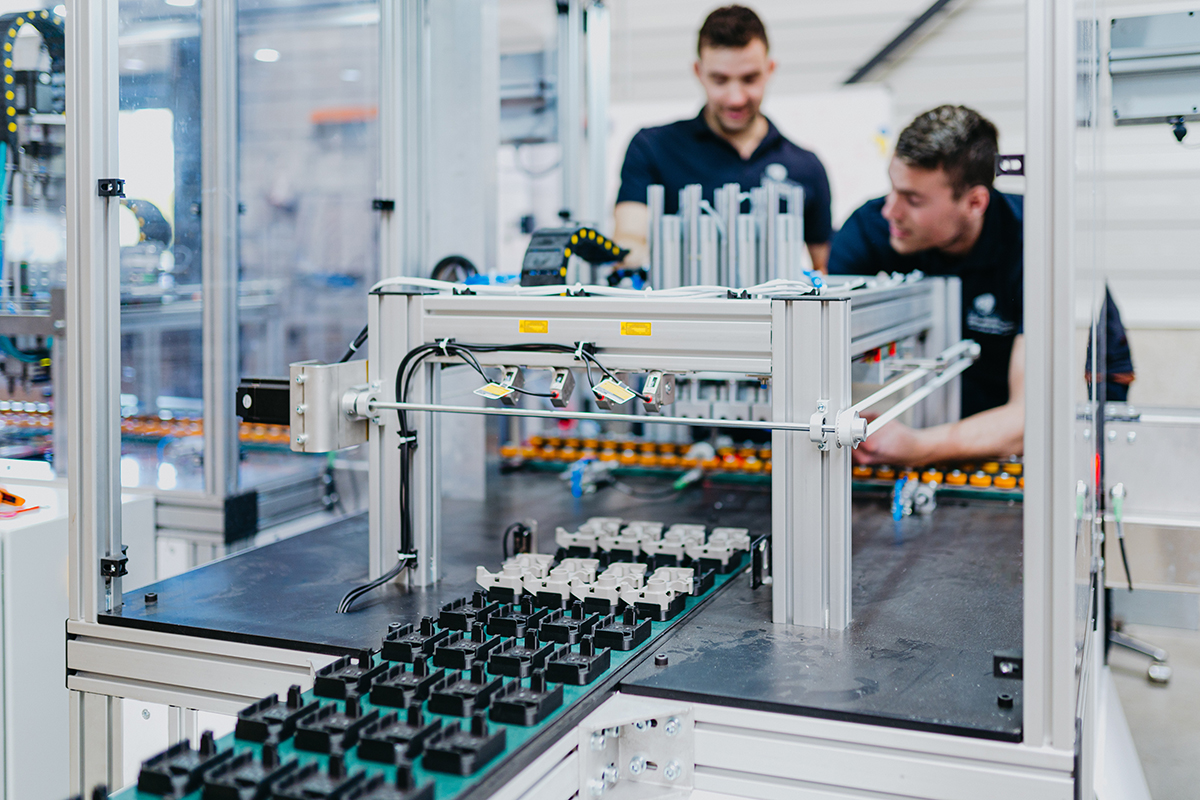

Custom-made plastics

There are all sorts of shapes and sizes of plastic used for different products and components. Perhaps you also find yourself wondering how something was made. Custom-made plastics are created by injection moulding machines. Working with an injection mould enables development of the most complex plastic products – and also the strongest. With today’s highly advanced techniques, we can realise mass production in a short time using various production techniques. Custom-made plastics are suited to a wide range of products and components. You see them, or even use them, every day.