What can you do with 3D printing?

3D printing is a fast and accessible way to bring ideas to life. Whether you need a prototype or a small functional series, we can deliver a ready-to-use model within just a few working days – perfect for testing or presenting. With no mold costs and complete design freedom, 3D printing is ideal for small quantities and short development cycles.

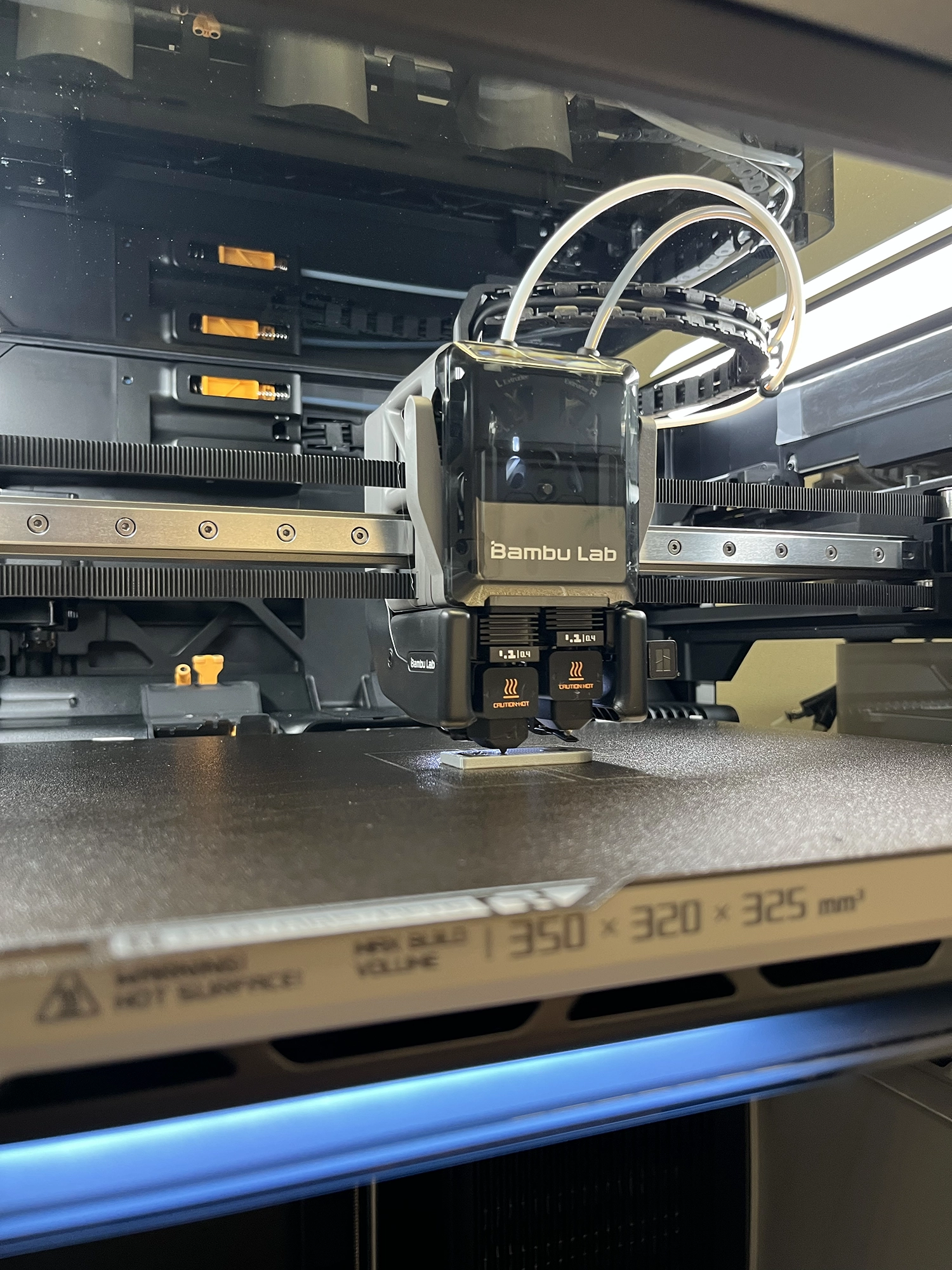

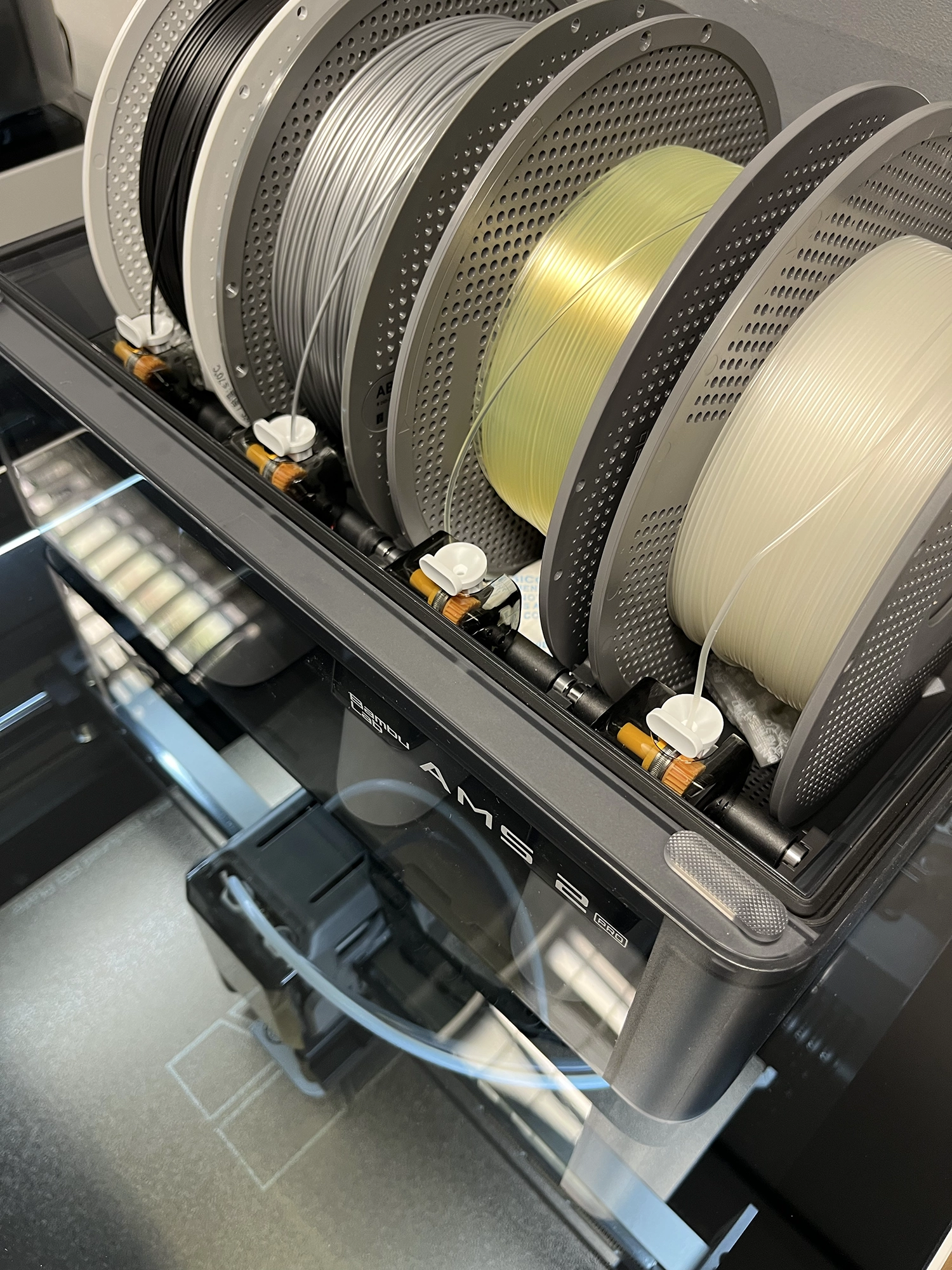

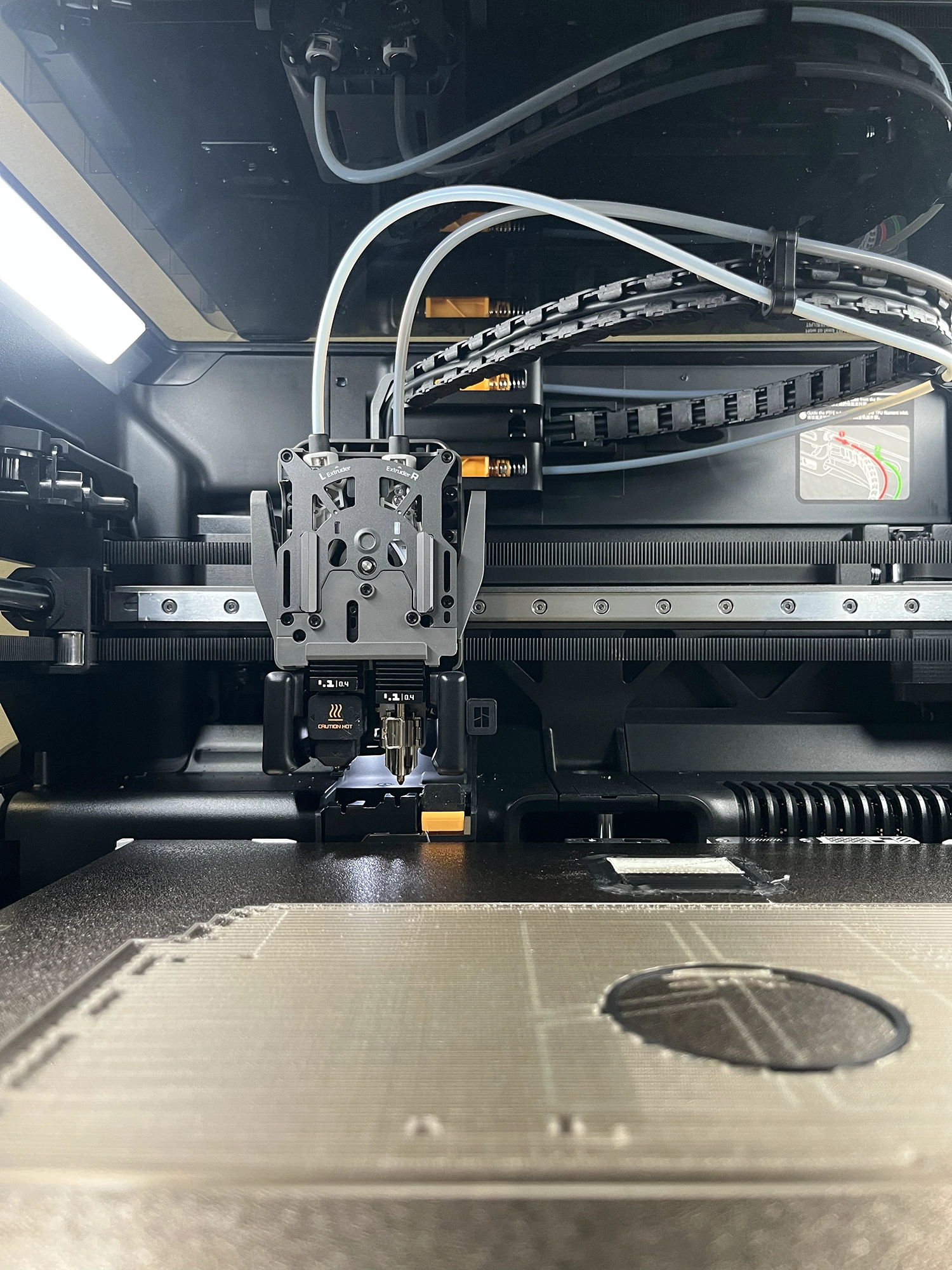

At Wicro, we use FFF technology: a precise printing method where plastic filament is built up layer by layer. Together, we’ll determine the right material – from PLA to fiber-reinforced plastics – and we’ll actively support you in design, application, and manufacturability. We can also develop and apply virtually any color you want during the 3D printing process, fully tailored to your product or brand identity.