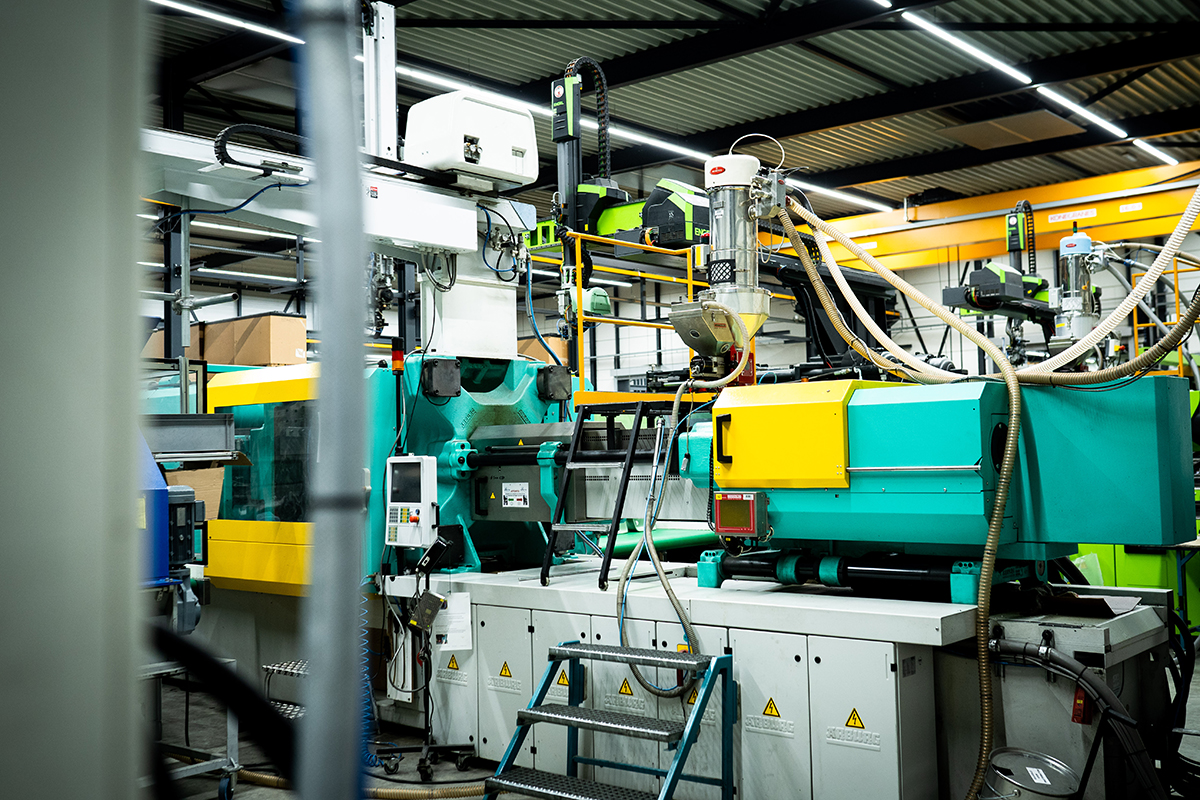

Injection mould costs

Injection moulding cannot be performed without a mould, so the cost of an injection mould is the first cost that needs to be taken into account. An injection mould is an investment that will pay for itself in the long run.

Injection moulding costs are determined by the complexity of the product or component, the simplicity of the mould, and the material used to create the injection mould. The mould itself can be made of hardened steel or aluminium, with aluminium being the cheaper option. The multiplicity of the mould refers to the number of products or components in one mould. Several shapes can be incorporated into a single injection mould; this determines the cost of both the mould and the component.

Costs begin at €3,000 for a simple injection mould. Very complex moulds made of the best materials can cost up to €150,000. This is a significant difference, but with a good plan the expense can be recouped rapidly.